Carbon Storage

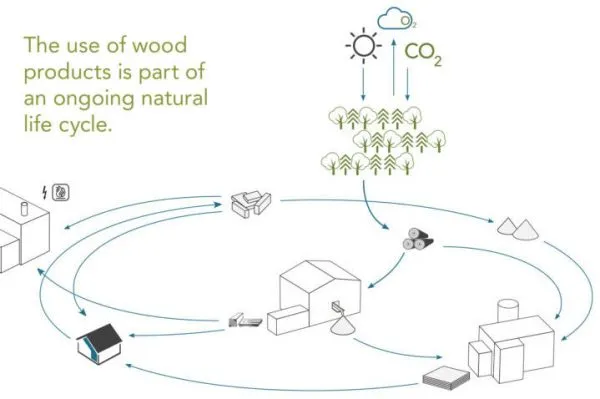

For the environmentally conscious Architect, Designer, or Engineer, Plywood is a logical choice. With the ability to store carbon for its entire service life, using sustainably sourced timber can help tackle climate change and transition to a low-carbon economy. Choosing plywood in design and construction can help tackle climate change in several ways. One of the most important is that wood stores carbon.

Growing trees absorb carbon dioxide from the atmosphere, emit oxygen, and store carbon. Carbon remains locked in the wood for the life of the piece of timber until it rots, decays, or is burnt.

India’s native forests, timber plantations, and wood products are all net absorbers of greenhouse gases, reducing India’s overall greenhouse gas emissions by almost 5% annually. The combination of carbon sequestration in growing trees and the long-term carbon storage in wood products represents a significant store of carbon for India.

Low Embodied Energy

Embodied energy is usually sourced from fossil fuels and it sums up to become a significant component of the total life cycle energy consumption of a material. Generally, the more highly processed a material is, the higher its embodied energy.

The embodied energy of a building can be lowered by using locally available, natural materials that are both durable and recyclable, with a design that incorporates components that are easy to recover and reuse, within a structure that is easy to dissemble and dismantle.

Timber can create buildings with low embodied energy. It is often locally available and it is natural, durable, and recyclable. Its versatility and light weight means it can be designed to be easy to disassemble, recover, reuse, and or recycle.

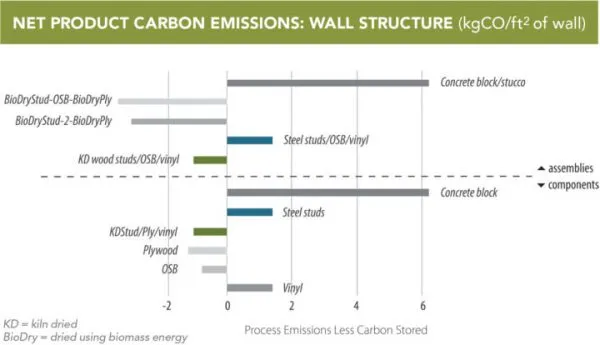

Recent research by the Cooperative Research Centre for Greenhouse Accounting compared the amount of greenhouse gas emissions generated by the manufacture of timber products, with the amount of emissions generated by other common building materials. The results showed that by substituting timber in the construction of a typical family home, greenhouse gas emissions, equivalent to up to 25 tonnes of carbon dioxide, could be saved.

The environmental benefits of such reuse are obvious – not only is the service life of the timber extended (and with it the need for a new product eliminated) but in addition, the carbon contained within the recycled timber is stored for the life of the new product.

Recycling Wood Waste

In the plywood industry rarely is there such a thing as a wasted piece of wood. It is increasingly common practice to recycle and reuse what would otherwise be timber residue into new products and applications. The versatility of timber is no better demonstrated than in the variety of second-life products it makes its way into.

Particleboard manufacturers increasingly utilize recycled wood packaging and off-cuts in the production of new particleboards. Animal bedding, mulch, and composts continue to make excellent use of the natural moisture-retaining properties of timber and more & more timber salvaged in the demolition of large buildings is finding new life as features in contemporary designer buildings.

The environmental benefits of such reuse are obvious – not only is the service life of the timber extended (and with it the need for a new product eliminated) but in addition, the carbon contained within the recycled timber is stored for the life of the new product.

When wood residue from timber processing cannot be recycled it can still be used to produce biomass energy. Biomass energy is renewable energy, sourced from natural materials like wood, which is then generated into heat or electricity.

The National Timber Product Stewardship Group states that the energy produced from the combustion of renewable timber is considered to emit over 50 times less greenhouse emissions than the combustion of black coal and over 30 times less than natural gas when used in industrial facilities.

Wood residue used in energy production provides twofold environmental benefits. Firstly, its use reduces industry reliance on environmentally damaging fossil fuels, in turn preventing the release of long-term carbon storage from sources that cannot be replenished. Secondly, the energy itself omits far fewer greenhouse gas emissions than typical alternatives.

Life Cycle Analysis

Timber’s low embodied energy is yet another reason to choose timber as a positive choice for our environment. Embodied energy is described as the energy consumed in manufacturing and transporting materials to the site for construction purposes. It includes the extraction and processing of raw materials, along with manufacturing, transport, and product delivery processes. Embodied energy is usually sourced from fossil fuels and it sums up to become a significant component of the total life cycle energy consumption of a material. Generally, the more highly processed a material is, the higher its embodied energy.

The embodied energy of a building can be lowered by using locally available, natural materials that are both durable and recyclable, with a design that incorporates components that are easy to recover and reuse, within a structure that is easy to dissemble and dismantle.

Timber can create buildings with low embodied energy. It is often locally available and it is natural, durable, and recyclable. Its versatility and light weight means it can be designed to be easy to disassemble, recover, reuse, and or recycle.

Recent research by the Cooperative Research Centre for Greenhouse Accounting compared the amount of greenhouse gas emissions generated by the manufacture of timber products, with the amount of emissions generated by other common building materials. The results showed that by substituting timber in the construction of a typical family home, greenhouse gas emissions, equivalent to up to 25 tonnes of carbon dioxide, could be saved.